Fiber Laser Cutting PAGE 9

Precision Fiber Laser Cutting

Larger Size Systems

4X8, 5X10, 6X10+ Pallet Exchange

Up to 40kW

Class I or Class IV

Larger Size Systems

4X4, 5X5, 4X8, 5X10+

Up to 40kW

Class I or Class IV

Mid-Size Systems

4X4

Up to 30kW

Class 1

Mid-Size Systems

4X4

Up to 8kW

Class 1

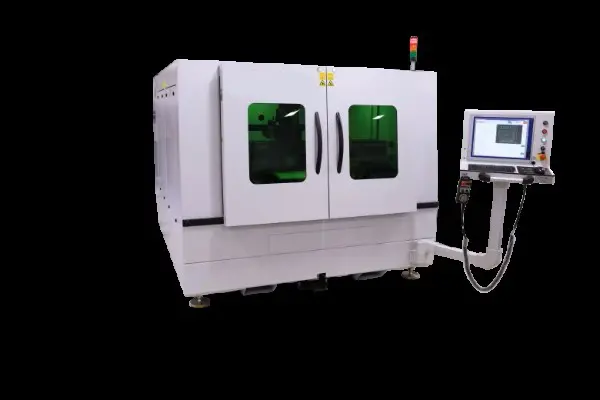

Lower Priced Systems

4X4

Up to 4kW

Class 1

Lower Priced Systems

4X4

Up to 4kW

Class 1

Fiber Laser Cutting

Laser cutting is cost-effective for even small-batch runs. The programmable laser profile provides small spot sizes and localized laser energy, enabling minimal kerf widths, minimal heat-affected zones, and high feed rates.

Whether your need is micro-cutting, macro-cutting, or both, we offer a range of advanced Laser Cutting Systems. Systems are available with standard configurations or can be custom-configured to your requirements, including integrated automation, pallet exchanges, and various material handling configurations. Some systems utilize linear motors, which have greater acceleration compared to ball screw configurations with greater reliability. With a wide range of powers, systems can cut up to over 1” thick steel.

Systems Are Available With:

Industries We Serve:

Metal Materials: